Ivanpah Solar Electrical Generating System (ISEGS)

ISEGS is a 392 MW solar concentrated solar power (CSP) plant; with three separate solar power towers. CSP is a form of solar thermal power production).

Ivanpah is a "hybrid solar plant", relying on both solar thermal CSP, and a relatively small share of natural gas backup power (gas is also used as a fuel at night to keep ISEGS primed, and to heat water used in the tower boilers).

Jointly owned by NRG Energy, Google, and BrightSource Energy, the Ivanpah Solar Electric Generating System (ISEGS) is located near the California and Nevada border in the Mojave Desert. ISEGS provides 392 MW of solar thermal energy to power over 140,000 homes. When ISEGS was first made operational in 2010, it was the largest solar thermal plant in the world, and the first concentrated solar plant to use solar power tower technology in the United States.

ISEGS officially broke ground on October 27, 2010; and opened for business in February of 2014. ISEGS began operations in 2014 with facilities that stretch over 3,500 acres, making ISEGS one of the world's largest solar thermal plants (large CSP plants are also being developed, or are operational, in Spain, Dubai, Morocco, and China - among other locations). ISEGS produces enough clean, renewable electricity to power over 140,000 homes during peak hours, and almost double that amount during off-peak hours.

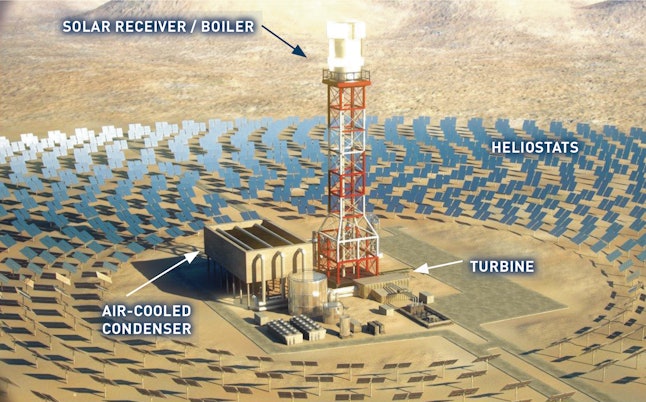

ISEGS Structural Components

ISEGS was developed as a three-unit CSP plant. Each CSP unit relies on solar receivers filled with water nestled atop central towers heated by concentrating solar power.

By using over 300,000 mirrors (known as heliostats), to harness the sun’s energy, and focus sunlight directly onto the solar receivers at strategic angles, the water in the receivers is heated to such high temperatures that it dissolves into steam. From there, the steam is then piped into conventional turbines to generate electricity.

Despite being one large solar plant, the project was broken down into three separate CSP units; each with its own 400-plus foot tower affixed with water-filled receivers/ boilers. The specific tower technology used is Luz Power Tower 550, which was developed by BrightSource Energy.

The 3 solar power tower units of ISEGS

Each of the 3 separate CSP units in ISEGS includes:

- a solar receiver (solar power tower); a vast array of heliostats

- one Rankine-cycle reheat steam turbine that receives live steam from the solar boilers; and reheats steam from one solar reheater located in the power block at the top of its own tower adjacent to the turbine

- a raw water tank with a 250,000-gallon capacity; 100,000 gallons to be used for the plant and the remainder to be reserved

- a small onsite wastewater plant (located in the power block); that treats wastewater from multiple local wastewater streams for use in ISEGS

- a natural gas-fired start-up boiler to provide heat for plant start-up; and during temporary cloud cover

- an air-cooled condenser, or "dry cooling" unit, to minimize water usage in the site's desert environment

- auxiliary equipment including feedwater heaters, a deaerator, an emergency diesel generator, and diesel-powered emergency fire pumps

Awarded Plant of the Year by POWER Magazine in 2014, the Ivanpah CSP plant is proof that large-scale solar thermal projects are not only feasible, but cost-efficient and energy-efficient as well. This massive complex was constructed in 4 years; and added jobs to a somewhat dwindling local economy. The development ISEGS involved about 1,000 jobs at the peak of construction, the creation of about 100 permanent jobs; and total economic benefits of about $3 billion to local economies. The 392-megawatt ISEGS solar complex is revolutionizing the solar energy industry, proving that large-scale CSP projects can both thrive and surpass expectations.

ISEGS avoids over 400,000 tons of carbon dioxide emissions per year (compared to emissions from a similar sized fossil fuel power plant); the equivalent of removing 70,000 cars from the road annually. Adding to the environmental-friendliness of ISEGS, it uses dry cooling to condense steam; and by doing so, it consumes significantly less water than other similar steam-powered thermal plants.

Additionally, ISEGS features a small on-site wastewater treatment facility for water reclamation, supplying some of the water for ISEGS to run. Although ISEGS strives to have operations be as eco-friendly as feasible; when it's cloudy, or the sunshine is otherwise not readily available, the plant is able to run on natural gas - in addition to the stored thermal energy from the solar concentrating power system.

Please also see: