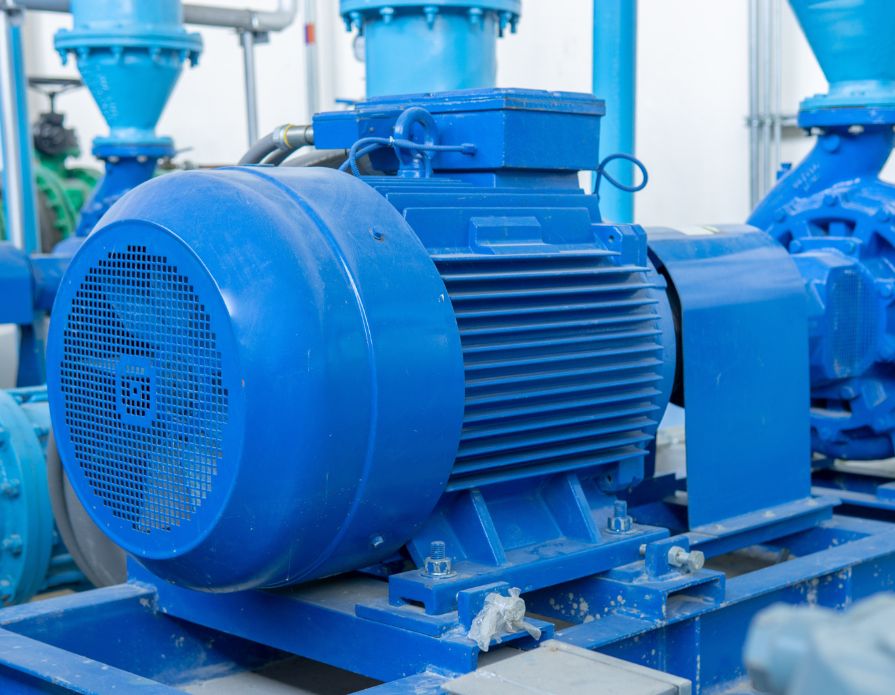

Tips for Maintaining and Protecting Your Electric Motor

Electric motors are the heartbeats of countless machines and systems within industrial sectors, driving everything from the smallest gadgets to the largest industrial equipment. Their widespread application speaks volumes about their importance, making maintenance a matter of operational efficiency, sustainability, and cost-effectiveness.

The purpose of electric motors extends beyond functionality; they represent a significant investment in an operation’s infrastructure. These tips for maintaining and protecting your electric motor will highlight the importance of wise decision-making in managing electric equipment.

Regular Cleaning

Keeping your electric motor clean is one of the simplest yet most effective practices for maintaining its efficiency. Dust, dirt, and debris can accumulate in and around the motor, leading to overheating and potentially causing damage. Use soft brushes and a vacuum cleaner designed for electronic equipment to remove dust from the surface and accessible interior parts. For stubborn grime or grease, use a cloth dampened with mild detergent. Finally, prevent moisture from entering the motor’s internal components.

Lubrication

Lubrication reduces friction in motor bearings; this aspect of maintenance significantly impacts the lifespan and performance of an electric motor. It’s essential to use the correct type of lubricant as outlined by the manufacturer, and adhere to a lubrication schedule. Over-lubrication can be just as detrimental as under-lubrication; finding the balance is key to caring for the machinery. This practice supports operations, prevents wear and tear, and prolongs the motor’s service life.

Implementing Protection Devices

Implementing protection devices is a sophisticated yet essential strategy for maintaining and protecting electric motors. Protection systems preserve the motor and minimize the risk of operational disruptions and safety hazards. A guide to electric motor frame sizes can assist in this process by providing detailed information on the motor’s physical dimensions and capacity.

Regular Inspections

Routine inspections allow for the early detection of potential issues, such as wear and tear on components, misalignments, and electrical or mechanical imbalances. Creating a checklist that includes inspecting the motor’s physical and electrical state and vibration analysis can provide insights into its operational capacity. Scheduled maintenance checks are also crucial for recalibrating and adjusting to ensure the motor runs efficiently.

Understanding Load and Operating Conditions

Electric motors operate within specific load and environmental parameters, which contribute to sustainable construction waste management. Operating beyond these parameters can significantly shorten their life span by inducing excessive heat, vibration, and wear on their components. To manage load conditions, regularly monitor the motor’s performance metrics against its rating. This includes the mechanical load and factors such as the voltage supply consistency, frequency, and phase alignment for motors powered by AC sources.

By adhering to these tips for maintaining and protecting an electric motor, operators and maintenance personnel can significantly enhance their durability and efficiency. Beyond routine care, understanding their intricacies empowers users to select and maintain motors appropriately for their applications, ensuring reliability and performance in the long run.